Staff profile

David Pattinson

Technical Manager (Teaching & Research)

| Affiliation | Telephone |

|---|---|

| Technical Manager (Teaching & Research) in the Department of Physics | +44 (0) 191 33 42227 |

Biography

Responsibilities within the Department

My key duties and responsibilities as a Research Technician are to provide technical support and expertise for various research groups within the department, namely

- Centre for Materials Physics (CMP)

- Atomic & Molecular Physics (AtMol)

- GJ Russell Electron Microscopy Facility (GJREMF)

Other roles, committees and working groups

- Departmental Hazardous Waste and WEEE Advisor and Co-ordinator

- Member of the Departmental Health & Safety Committee

- Member of Departmental Technical Supervisors Working Group

Qualifications

- ILM (Institute of Leadership and Management), Level 3 Award and Certificate in First Line Management – (Pending Completion)

- ILM (Institute of Leadership and Management), Level 2 Certificate in Team Leading

- ILM (Institute of Leadership and Management), Level 2 Award in Team Leading

- BSc Physical Electronics (Applied Physics)

- BTEC HNC – Electronic Engineering

- BTEC ONC – Electrical & Electronic Engineering

Work Related Training Certificates

- Arco – Manual Handling in the Workplace

- Gas Safe – Practical Compressed Gases Safety Awareness

- Gas Safe – Laboratory Gases Safety Awareness (Piped Systems)

- Gas Safe – Compliance with Cryogenic Pressure Systems

- HEaTED – Introduction to Scanning Electron Microscopy

- Buehler - Materials Preparation for Microstructural Analysis (MPMAC)

- Struers – The Professional Materialographer Course

- Logitech – Materials Processing

Personal Statement

After leaving school in 1983 I started a 1 year government youth training scheme (YTS) with Durham University in the Department of Physics, acquiring a broad range of technical skill sets within the undergraduate teaching laboratories, research laboratories, mechanical and electronic workshops as well as audio-visual. After successful completion of my YTS scheme I continued working at Durham University moving to the Department of Applied Physics & Electronics in September 1984 on a two year contract as a trainee research technician based in the microelectronics clean-room, specialising in silicon wafer technology during which time I attended New College Durham on day release successfully completing an ONC in Electrical and Electronic Engineering. In October 1986 I became a permanent member of the department embarking on a further two year intensive training programme as a trainee research technician during which time I attended New College Durham on day release successfully completing an HNC in Electronic Engineering. After successful completion of my two years training I became a fully qualified research technician remaining with the department until August 1991 when I took up a post as a research technician in the Department of Physics where I remain to this day. In July 1996 I was awarded the degree of BSc Physical Electronics (Applied Physics) by Part-time Study from the University of Northumbria at Newcastle. I am proud to state that as of 24 September 2015 I will have completed 31 years continuous employment with Durham University.

Technical Skills

- Electron Microscopy - Image Aquisition and Analysis Techniques using Hitachi SU70 SEM

- Materials Preparation for Microstructural Analysis (MPMAC)

- Precision Cutting, Grinding and Polishing of a wide range of materials and samples

- Installation, Maintenance, Fault Finding and Repair of specialist scientific research equipment

- Installation and Maintenance of crucial services including compressed gas lines, vacuum lines, high purity water systems, cryogenic liquids and exhaust of waste gases

- Portable Appliance Testing (PAT) of research instrumentation and equipment

- Design, Building, Maintenance and Fault Finding of Vacuum Systems

- Vacuum Leak Detection using newly purchased Pfeiffer ASM 340 Helium Leak Detector

- Glass Blowing – Sealing of silica ampoules for crystal growth

Specialised Areas of Expertise/Interest

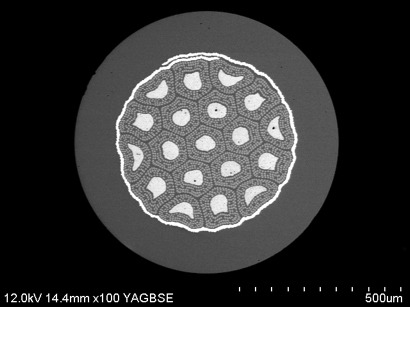

The Superconductivity research group within the Centre for Materials Physics (CMP) are the UK representatives of the European magnet technology experts reporting to the International Thermonuclear Experimental Reactor (ITER) and the Fusion 4 Energy (F4E) European Commission after being awarded a contract as the European Reference Laboratory (ERL).

The ERL is contracted to F4E to provide comprehensive characterisation measurements on the superconducting strands to be used in the ITER Tokomak magnet system. Part of the characterisation of the superconducting strands is to calculate the Cu / Non-Cu ratio of the cross-sectional area carried out using Electron Microscopy techniques. My involvement in the research project is to provide the electron micrograph images using the Hitachi SU70 SEM.